Two Renowned Muskoka Businesses Combine Their Impeccable Craftsmanship in a Major Renovation, With Outrageously Beautiful Results

Built by Brian Hoar Inc. Millwork and Moulding by LaserTrim

The job Jeff – owner of custom millwork and moulding manufacturer LaserTrim Muskoka Inc. – is referring to involves an extensive renovation to a Muskoka cottage on one of the Big Three lakes. Unlike a straightforward tear-down or addition, this project saw the builder – Muskoka’s Brian Hoar Inc. – demolishing a 1,400 square-foot section in the centre of an existing property and replacing it with 2,500 square feet of new space to house the cottage’s kitchen and Great Room.

“There are obvious challenges to demolishing part of an existing structure,” explains Josh Pearcey, director and project manager at Brian Hoar. “In this case, we not only had to be careful not to damage the integrity of the remaining parts of the building, but there was a stone fireplace that the clients wanted to preserve.” This meant performing the demolition to exacting standards.

Getting Every Little Thing Right

The subsequent addition features extensive timber framing which, in combination with stonework in two fireplaces and on accent walls, gives the area a majestic Great Hall aesthetic. “Creating expansive spaces is one of the key hallmarks of timber framing,” explains Josh, “but executing them in such a way that the resulting space remains inviting and comfortable can be a challenge.”

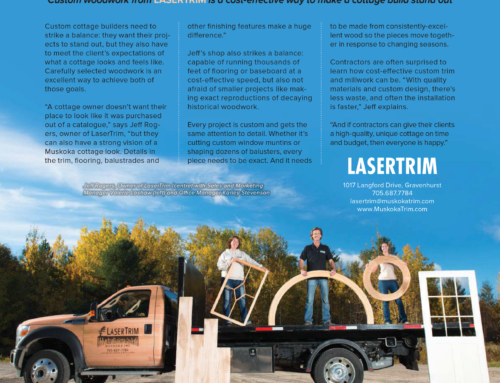

Enter Jeff Rogers. Brian Hoar Inc. brought Jeff and his team at LaserTrim on to manufacture and supply the project’s flooring, trim, mouldings, and ceiling boards, as well as a few other highly customized wood elements. “Part of the key to achieving an exceptional project is having highly skilled subtrades on hand to furnish to the level of detail that is required of us by our clients,” says Josh. Details of the type Jeff’s team provides may not always be immediately obvious when you enter a room, but if they’re done right, they contribute in immeasurable ways to the overall feel of the space.

Setting the Bar High

Jeff’s exacting standards have developed over many years. He started out in the business as a carpenter but was consistently frustrated by the products he was installing. “We’d have to put wedges on the walls to try and force the boards together because the stuff just wasn’t milled with the proper tolerances or it was all bent or crooked,” he recalls. The root of the problem was apparent: most people milling the lumber had never installed it themselves. So, Jeff decided to specialize.

“I’m not a builder. I do what I do and that’s all I do,” he explains. “I’m not going to hire the landscaper to do my addition. I’m not going to hire the builder to do my landscaping. Bottom line: If you are hiring specialists to ensure quality, you should source those tradespeople who specialize exclusively in that one specific aspect of the project, or product, at hand.”

It’s a philosophy that resonates throughout Muskoka’s most refined cottages, where the property owners are equally concerned with the quality and value of what they’re getting as they are with the price. In any case, Jeff believes that factoring in the amount of waste and unnecessary labour hours resulting from low-grade product, his elite-level craftsmanship is highly competitive.

If You Want Something Done Right

Having worked as an installer, one of Jeff’s frustrations when buying material from lumber stores was that he’d end up with pieces from four or five different runs. “It wasn’t coming off the same machine, or it was a different batch of lumber. It was a real hodgepodge of stuff,” he says. “I like to run it so it’s all coming off the same cutters, the same machine, and if we need more later we take a sample and make sure it matches exactly.” The payoff for that kind of accountability is evident in LaserTrim’s contribution to Brian Hoar’s stunning timber frame addition, which included supplying clear pine for the trim, cedar for the exterior, and cherry flooring. “Outside, all the corners, frieze boards, sills, and curved tops — it was important that we manufactured all components exactly to specification,” Jeff recalls. He is now at work on an intricate 4-foot compass inlay for the floor. And Brian Hoar Inc. is currently working on a further 4,400 square-foot addition to the property.

When asked if Jeff anticipates that the current trend toward modern architecture in Muskoka will affect his business, he shrugs it off. “We manufacture quality architectural wood products,” he says. “It doesn’t matter what your style is. My whole thing is to be able to give people whatever they need to get the look they want.” – Hideaways